Mastering Venison: The Art & Science Of Johnson Deer Processing

For many hunters, the thrill of the chase culminates not just in a successful harvest, but in the meticulous process that transforms wild game into delicious, wholesome food. This crucial stage, often overlooked in its complexity, is where quality truly matters. Whether you're a seasoned outdoors enthusiast or new to the hunting tradition, understanding the intricacies of proper venison handling is paramount. That's precisely where a dedicated service like Johnson Deer Processing steps in, offering the expertise and facilities to ensure your hard-earned venison is handled with the utmost care, hygiene, and precision.

The journey from field to table is fraught with potential pitfalls, from improper field dressing that can compromise meat quality to inadequate storage leading to spoilage. Entrusting your harvest to a professional deer processing service isn't just about convenience; it's about safeguarding your investment, maximizing the yield, and ensuring the safety and palatability of the meat for your family and friends. A reputable processor understands the nuances of venison, from optimal aging techniques to custom cuts that cater to every culinary preference, transforming a raw harvest into a culinary treasure.

Table of Contents

- The Critical Role of Proper Deer Processing

- Why Choose a Professional Johnson Deer Processing Service?

- Understanding the Processing Journey at Johnson Deer Processing

- Custom Cuts and Culinary Delights: Maximizing Your Harvest

- Beyond Basic Butchering: Value-Added Services

- Essential Considerations for Hunters Before and After the Harvest

- The Economic and Ethical Impact of Quality Deer Processing

- Selecting the Right Johnson Deer Processing Partner: What to Look For

The Critical Role of Proper Deer Processing

The moment a deer is harvested, a race against time begins. The quality of the venison, its flavor, texture, and safety, hinges almost entirely on how it's handled in the hours and days following the kill. Improper processing can lead to a host of issues, from "gamey" flavors caused by poor bleeding or gutting, to bacterial contamination from unsanitary conditions, and even significant meat loss due to mishandling. Without immediate and correct attention, even the finest wild game can quickly become unpalatable or, worse, unsafe for consumption.

This is not merely about butchering; it's a comprehensive process that includes proper cooling, aging, cutting, and packaging. Each step plays a vital role in preserving the meat's integrity. For instance, rapid cooling prevents bacterial growth, while controlled aging (hanging the carcass at specific temperatures) tenderizes the meat and develops its flavor profile. Cutting the meat into appropriate portions and vacuum-sealing it correctly extends its freezer life and prevents freezer burn. Neglecting any of these steps can diminish the overall quality of your venison, turning a potential culinary delight into a disappointing experience.

From Field to Freezer: Initial Steps

The initial steps taken in the field are arguably the most critical. Immediately after the harvest, proper field dressing is essential to cool the carcass rapidly and remove internal organs that can cause spoilage. This involves carefully gutting the animal, often removing the heart, liver, and lungs, and ensuring adequate airflow to the body cavity. Hunters should aim to cool the carcass as quickly as possible, ideally by hanging it in a shaded, well-ventilated area or by placing ice packs inside the cavity if temperatures are high. Transporting the deer quickly and cleanly to a processing facility is also paramount to maintaining its quality. These initial actions lay the groundwork for the rest of the processing journey and directly impact the final product you receive from a service like Johnson Deer Processing.

Why Choose a Professional Johnson Deer Processing Service?

While many hunters take pride in processing their own deer, the advantages of utilizing a professional service like Johnson Deer Processing are compelling. These facilities are equipped with specialized tools, temperature-controlled environments, and experienced butchers who understand the unique characteristics of venison. This professional approach ensures not only maximum yield but also superior quality and safety that can be difficult to achieve in a home setting.

Expertise and Efficiency

Professional deer processors possess an unparalleled level of expertise. They are skilled in breaking down a carcass efficiently, minimizing waste, and maximizing the amount of usable meat. Their knowledge extends to various cutting techniques, allowing them to produce a wide array of cuts, from prime steaks and roasts to ground venison and specialty products like jerky or sausages. This efficiency means you get more value from your harvest. Furthermore, they can process multiple deer simultaneously, offering a quick turnaround time, which is particularly beneficial during peak hunting seasons when time is of the essence for proper cooling and handling.

Hygiene and Food Safety Standards

Perhaps the most critical advantage of a professional Johnson Deer Processing facility is their unwavering commitment to hygiene and food safety. These operations adhere to strict sanitation protocols, often mirroring those found in commercial meat packing plants. This includes regular cleaning and sanitization of equipment, temperature-controlled environments to inhibit bacterial growth, and proper handling procedures to prevent cross-contamination. For instance, surfaces and tools are typically stainless steel and easy to clean, and staff wear appropriate protective gear. This meticulous attention to cleanliness significantly reduces the risk of foodborne illnesses, providing hunters with peace of mind that their venison is safe and wholesome for consumption. In a world where health is everything, ensuring the safety of your food supply is non-negotiable.

Understanding the Processing Journey at Johnson Deer Processing

When you drop off your deer at a reputable facility like Johnson Deer Processing, it embarks on a carefully orchestrated journey designed to optimize its quality and prepare it for your freezer. This process typically begins with immediate tagging and weighing, ensuring your deer is uniquely identified and tracked throughout its stay. The carcass is then moved into a large, temperature-controlled cooler, often set just above freezing, for initial chilling and aging. This crucial step, known as "hanging," allows the natural enzymes in the meat to break down connective tissues, resulting in a more tender and flavorful product. The duration of this aging process can vary depending on the deer's condition, the desired tenderness, and the processor's recommendations, usually ranging from a few days to over a week.

Once properly aged, the deer moves to the cutting room. Here, skilled butchers meticulously skin the animal, remove any damaged or undesirable parts, and then break down the carcass into primal cuts. This is where the artistry truly comes into play, as experienced processors know precisely how to maximize yield and prepare cuts that are best suited for various culinary applications. Following the primary breakdown, the meat is further processed according to the hunter's specific requests, which might include deboning, trimming, and grinding. Every step is executed with precision, aiming to deliver a product that meets the highest standards of quality and prepares your venison for long-term storage.

Custom Cuts and Culinary Delights: Maximizing Your Harvest

One of the significant advantages of using a professional deer processor is the ability to request custom cuts. Unlike generic processing that might simply yield ground meat, a specialized service like Johnson Deer Processing allows you to dictate how your venison is prepared. This means you can get specific cuts tailored to your cooking preferences, whether you desire tenderloin steaks, backstrap roasts, stew meat, or even bone-in cuts for specific recipes. This level of customization ensures that every part of the deer is utilized effectively and transformed into the most desirable form for your kitchen.

Beyond standard cuts, many processors offer a range of value-added products that transform raw venison into gourmet items. Imagine turning tougher cuts into delicious, lean ground venison, perfect for burgers or chili. Or perhaps having your venison transformed into savory sausages, infused with various spices and flavors, or cured into a robust jerky, ideal for snacks or trail food. These specialty items not only expand your culinary repertoire but also make the most of cuts that might otherwise be less appealing. By offering these diverse options, a professional processor ensures that your deer harvest provides a wide array of culinary delights, making every meal an experience.

Beyond Basic Butchering: Value-Added Services

Modern deer processing extends far beyond just cutting and packaging. Many facilities, including top-tier operations like Johnson Deer Processing, offer an impressive array of value-added services designed to enhance your venison experience. These services can transform your raw harvest into a diverse range of ready-to-cook or ready-to-eat products, maximizing the utility and enjoyment of your game meat.

- Sausage Making: This is a popular option, allowing hunters to convert trim and tougher cuts into delicious sausages. Processors often offer various blends, from breakfast sausage to Italian or even specialty bratwurst, often mixed with pork fat for improved flavor and texture.

- Jerky Production: Venison jerky is a highly sought-after snack. Professional processors have the equipment and expertise to properly season, dehydrate, and cure venison into shelf-stable, flavorful jerky.

- Smoked Products: Some facilities offer smoking services for various cuts, adding a rich, deep flavor profile to roasts, hams, or even ground meat.

- Patty Making: For convenience, many hunters opt to have their ground venison pressed into patties, ready for the grill or pan.

- Vacuum Sealing: While often standard, high-quality vacuum sealing is a critical value-added service. It removes air, preventing freezer burn and significantly extending the shelf life of your venison, preserving its freshness and flavor for months, even years.

- Specialty Blends: Processors can mix venison with other meats, such as pork or beef, to create custom blends for ground meat, which can enhance flavor and fat content, making it more versatile for cooking.

These services not only provide convenience but also leverage the processor's specialized equipment and culinary knowledge, resulting in high-quality products that might be difficult or impossible to create at home. They represent a significant return on your hunting effort, turning a single harvest into a diverse pantry of venison products.

Essential Considerations for Hunters Before and After the Harvest

The responsibility for quality venison doesn't begin and end with the processor. Hunters play a crucial role in ensuring their harvest arrives at the processing facility in optimal condition. Understanding and implementing best practices both in the field and during transport is vital for preserving meat quality and safety. Your actions directly impact the final product you receive from Johnson Deer Processing.

Field Dressing Best Practices

The immediate steps taken after a successful harvest are paramount. Field dressing, the removal of internal organs, should be performed as quickly and cleanly as possible. This helps to rapidly cool the carcass, preventing bacterial growth and the spread of unwanted flavors from the gut cavity into the meat. It's crucial to avoid contaminating the meat with stomach or intestinal contents. Once gutted, the body cavity should be propped open to allow for maximum airflow, and any blood or debris should be wiped clean. If temperatures are warm, consider placing ice bags inside the cavity to accelerate cooling. Protecting the carcass from dirt, insects, and other contaminants during transport is also essential. Using a clean tarp or game bag can prevent hair and debris from adhering to the meat, making the processor's job easier and ensuring a cleaner final product.

Furthermore, understanding the local regulations regarding game transport and tagging is critical. Always ensure your deer is properly tagged as required by your state's wildlife agency before moving it. These initial, diligent efforts by the hunter are the foundation upon which a professional Johnson Deer Processing service can build, ensuring that your venison is not only safe but also delicious.

The Economic and Ethical Impact of Quality Deer Processing

Beyond the immediate benefit of delicious meat, choosing a professional deer processing service carries significant economic and ethical implications. Economically, it represents a wise investment. While there's a cost associated with professional processing, the value gained through maximized yield, superior quality, and extended shelf life often outweighs the expense. Improper home processing can lead to substantial meat loss due to spoilage, poor cuts, or freezer burn, effectively wasting a portion of your harvest. A professional service ensures you get the most out of every pound, translating to more meals and better value for your hunting efforts.

Ethically, responsible deer processing aligns with the core tenets of ethical hunting. Hunters have a moral obligation to respect the animal they harvest by utilizing its meat to the fullest extent possible. Wasting game meat due to poor handling or processing is antithetical to this principle. By ensuring your venison is processed to the highest standards, you honor the animal and the tradition of hunting. Moreover, supporting local businesses like a Johnson Deer Processing facility contributes to the local economy, creating jobs and sustaining a vital service for the hunting community. It fosters a responsible approach to wild game consumption, emphasizing sustainability, quality, and respect for natural resources.

Selecting the Right Johnson Deer Processing Partner: What to Look For

Choosing the right deer processing facility is a decision that directly impacts the quality and safety of your venison. Not all processors are created equal, and discerning hunters should look for specific indicators of quality and reliability. When considering a Johnson Deer Processing facility or any other processor, here are key factors to evaluate:

- Reputation and Experience: Seek out processors with a long-standing positive reputation in the hunting community. Ask fellow hunters for recommendations. Experience often translates to superior skill in butchering and a deep understanding of venison.

- Cleanliness and Hygiene: This is non-negotiable. A clean facility, both inside and out, is a strong indicator of good practices. Look for organized workspaces, clean equipment, and staff who adhere to sanitary procedures (e.g., wearing gloves, clean aprons). Don't hesitate to ask about their cleaning protocols.

- Temperature Control: Proper cooling and aging are crucial. Inquire about their cooler temperatures and aging practices. A facility with consistent, controlled refrigeration is essential for preventing spoilage and tenderizing meat.

- Customization Options: A good processor will offer a range of cuts and specialty products. Discuss your preferences for steaks, roasts, ground meat, sausages, or jerky. They should be willing to accommodate reasonable requests.

- Packaging Quality: High-quality packaging, especially vacuum sealing, is vital for long-term freezer storage. Ensure they use durable, airtight materials that prevent freezer burn.

- Turnaround Time: While quality shouldn't be rushed, a reasonable turnaround time is important, especially during peak season. Discuss their typical processing times and pickup procedures.

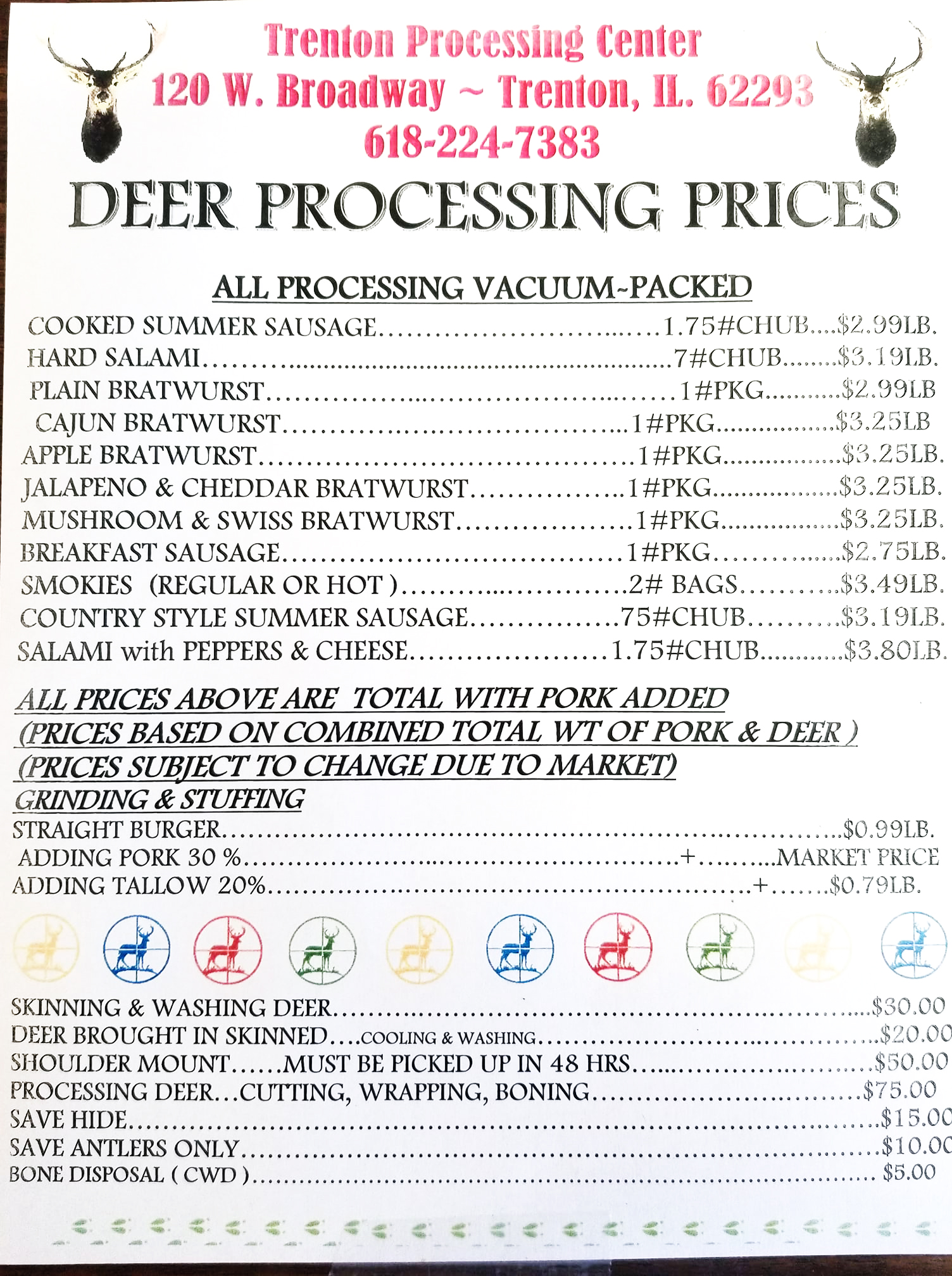

- Transparent Pricing: A reputable processor will have clear, upfront pricing for their services, including any additional charges for specialty products or expedited service.

- Customer Service: A friendly, knowledgeable staff who can answer your questions and provide advice demonstrates a commitment to customer satisfaction.

By carefully considering these factors, you can confidently select a Johnson Deer Processing partner that will transform your hard-earned harvest into a safe, delicious, and high-quality food source for your family, ensuring that your hunting efforts culminate in a truly rewarding culinary experience.

Conclusion

The journey of venison from the wild to your plate is a testament to the hunter's skill and dedication, but its successful completion hinges significantly on the quality of its processing. As we've explored, proper deer processing is far more than just butchering; it's a critical series of steps encompassing immediate field care, precise handling, controlled aging, expert cutting, and meticulous packaging. Entrusting this vital phase to a professional service like Johnson Deer Processing not only ensures the highest standards of hygiene and food safety but also maximizes the yield and culinary potential of your harvest, transforming it into a versatile and delicious food source.

By prioritizing expertise, efficiency, and adherence to stringent safety protocols, professional processors safeguard your investment and honor the animal. From custom cuts tailored to your preferences to value-added products like gourmet sausages and jerky, their services elevate the entire venison experience. For hunters, understanding the importance of these processes and making informed choices about their processing partner means enjoying the fruits of their labor with confidence and satisfaction. We encourage you to share your own experiences with deer processing in the comments below or consider exploring the benefits of professional services for your next harvest. Your insights contribute to a community dedicated to responsible hunting and quality food. Happy hunting, and enjoy your venison!

Phillips Outdoors Inc. added a... - Phillips Outdoors Inc.

Deer Processing | Trenton Processing Center | Carlyle IL

Step-by-step guide to processing deer meat